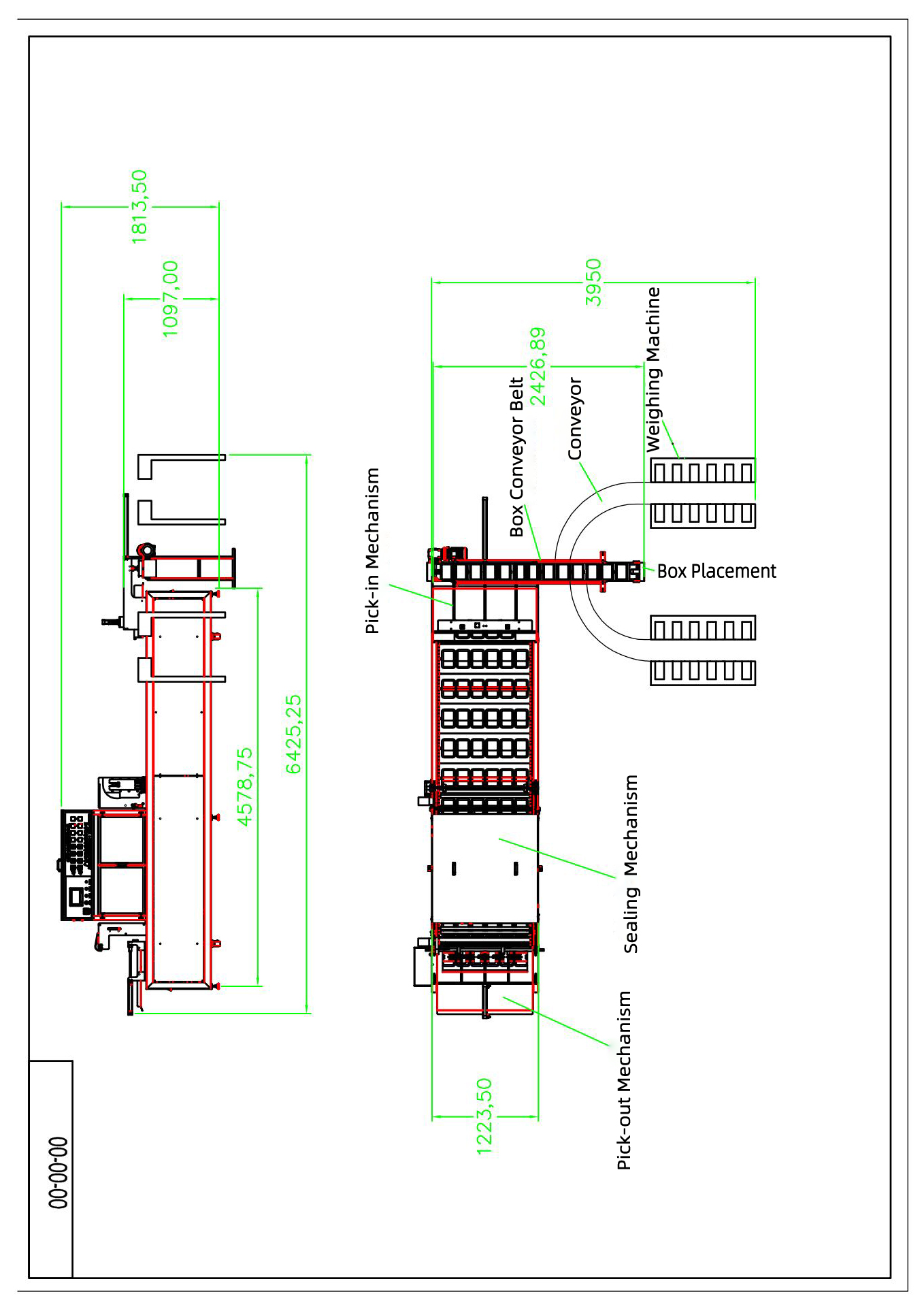

Customer Requirements

1. Sealing Products: Frozen Durian (Reference Picture)

2. Weight: 120g/box

3. Production: 4000 boxes / hour

4. 2 pieces / box (not confirmed)

5. The weight machine combined with the packing machine

6. Need to confirm the accuracy:

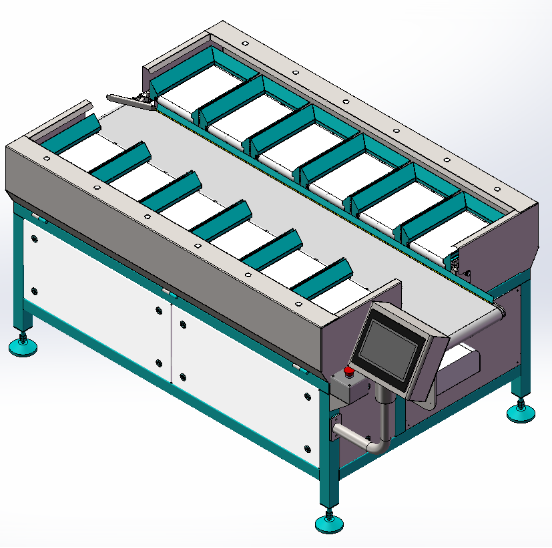

Application

It's suitable for weighing large block, strip and stem materials with poor fluidity, such as fish, noodles, shrimp and other aquatic products, meat products, medicinal materials and other materials.

Features

1. Using high-precision, high-standard special load cell.

2. Modular circuit board realizes intelligent multi-sampling stable mode, and the weighing is more accurate.

3. Intelligent fault alarm, convenient maintenance.

4. Concentrated discharge mode to ensure the relative concentration of materials and improve the running speed of the machine.

5. Intelligently customize the number of weighing trays to achieve double standards of weighing and counting.

Mechanical character

1. Double row linear layout, easy to operate by workshop staff.

2. Belt-type open weighing tray design structure can effectively solve the feeding of sticky or bulky materials with poor fluidity.

3. Visualize LED signal light, clear the feeding direction and feeding area, and effectively identify the current status of the corresponding tray.

4. Easy detachable conveyor belt, easy to clean.

5 HMI interface to facilitate self-learning and exchange of information.

Technical specification

|

Model |

JW-A12 |

JW-A14 |

|

Identify Code |

A12-2-5 |

A14-2-5 |

|

Weighing Range |

10-6000g |

10-6000g |

|

Accuracy *1 |

X(0.5) |

X(0.5) |

|

Max. Speed *2 |

30P/M |

25P/M |

|

Protection Class |

IP65 |

|

|

Weighing Belt Dimension |

300(L)x180(W) |

|

|

Control Panel |

10.1”Touch Screen |

|

|

Driving System |

Step Motor |

|

|

Power Requirement |

220V/800W/50/60Hz/3.6A |

|

|

Packing Dimension(mm) |

2200(L)x1200(W)x1160(H) |

2560(L)x1200(W)x1160(H) |

|

Gross Weight |

370kg |

450kg |

*1: Can refer to the national standard GB / T27738-2011 or the International Legal Organization No. 61 International

Recommendation OIML R61 2004 (E).

*2: Depends on product shape, product density, target weight etc.

This machine is a new type of full-automatic chain plate sealing machine developed and researched based on customer demands. It has high production efficiency. The sealing film can be selected as roll film or sheet film according to customer requirements. Either one can be chosen. The automatic mechanical hand places the sheet film, and the automatic hot sealing is carried out. The secondary sealing is more reliable. It can seal four boxes, six boxes or eight boxes at one time, greatly improving production efficiency and saving manpower. It is highly welcomed by a wide range of users.

Machine Function and Configuration:

1. This machine can seal six boxes at one time.

2. Six speeds: 3800-4300 pieces per hour

3. Working process: Manual box placement, automatic sealing, automatic product output.

4. The machine has a simple and elegant appearance, made of high-quality stainless steel 304, food-grade industrial 2B board with a brushed effect, dust-proof, rust-proof, acid-resistant, alkali-resistant.

5. We use pure hand polishing with fine workmanship. The machine box has small interface, no sharp corners. Our factory can guarantee the quality.

6. All parts are machined by CNC machines, accurate, standard, high precision, ensuring the long-term smooth operation of the entire machine and long service life.

7. The sealing chain is made of food-grade stainless steel 304, acid-resistant and alkali-resistant, can be directly rinsed with water, durable and not prone to deformation.

8. Frame structure: welded from thick steel structure, formed after one month of cooling, then machined on a planer type milling machine for the flat surface,solid and stable.

9. Sealing mold structure: stainless steel + aluminum oxide, durable, no rust, fast heat conduction.

10. The machine uses Servo motor to drive, has classic digital temperature controller, which makes temperature balanced.When the temperature at ±1 degree, it makes sealing reliable , no leakage and has good surface flatness effect.

11. Taiwan photoelectric eye tracking, ensuring the alignment and centering of the sealing pattern.

12. Delta PLC program control, Taiwan-style human-machine interface, with fault alarm function, easy to detect faults.

13. Sealing material: Any material that matches the box is acceptable, such as plastic composite heat-sealing film or aluminum foil composite film. The film thickness should be no less than 0.1MM.

14. Pressure range: 4 - 8 KG/CM2

15. Temperature range: 0 - 250 degrees

16. Power: 5000 - 8000W

17. Voltage: 380V 50Hz

18. Machine size: Customized models are subject to the final scheme drawing.

19. Packaging method: Wooden box

Gifted Accessories:

Ten heating tubes, two 40A solid-state ones, two 4V210-08 solenoid valves, two push-button switches, and thermocouple.

List of Electrical Accessories:

1.Human-machine interface: Siemens

2.PLC: Siemens

3.Host structure: Stainless steel 304 frame full thickness 3.0

4.Sealing mold: Six-series aluminum, 6061 aluminum alloy, non-casting acidified aluminum

5.Sealing hot plate: aluminum plate

6.Solenoid valve: Taiwan AirTac

7.Air switch: France Schneider

8.Main cylinder: Taiwan AirTac

9.Switch power supply: Taiwan Delta

10.Temperature control solid state: South Korea

11.Drive motor: Taiwan servo

12.Temperature control meter: Japan Fuji

13.Repeater: France Schneider

14.Circuit breaker: France Schneider

15.Frequency converter Taiwan Delta

Machine functions and configuration:

1. Six boxes per time.

2. Production speed: one out of one: 300-500 boxes/hour

3. Production process: manual box placement, automatic box entry, air pressure sealing, automatic waste discharge, automatic box top.

4. Program control, stable and reliable.

5. The human-machine interface is touch screen control, simple operation, and the machine operation status can be monitored at any time.

6. Classic digital display temperature control meter, temperature difference of plus or minus 5 degrees, good sealing effect.

7. Precision guide rail, smooth walking, accurate positioning.

8. Taiwan photoelectric eye tracking, electrical integration.

9. Sealing diameter: 30-250mm can be customized

10. Sealing material: plastic composite film, aluminum foil composite film, PP, PVC, PE, PET, PS are all OK.

11. The size of the sealing film is 2-3mm larger than the cup mouth, the sealing is tight, and the appearance is beautiful.

12. Air pressure range: 4-8KG/CM2

13. Temperature range: 0-300 degrees

14. Power: 1000-2000W

15. Voltage: 220V

16. Machine appearance: stainless steel

17. Net weight: 100kg (this is a custom-made model, the weight will be slightly different)

18. Packing size: length 156*width 101*height 85cm

19. Packing method: wooden box

20. Accessories: one instruction manual, one hexagonal wrench, one cross screwdriver, one paper tube.

Main configuration of the machine:

|

NO. |

Name |

Brand |

Origin |

|

1 |

Main Body |

Stainless Steel 304 |

Guangzhou |

|

2 |

Electric Switch |

Shuangke |

Nanjing |

|

3 |

PLC |

Homemade |

Guangzhou |

|

4 |

Display |

4.3-inch Color Touch Screen |

Guangzhou |

|

5 |

Relay |

Sanle |

Zhejiang |

|

6 |

Cylinder |

AirTac |

Taiwan |

|

7 |

Temperature Control Meter |

RKC |

Domestic |

|

8 |

Motor |

Taili |

Joint Venture |

|

10 |

Solenoid Valve |

AirTac |

Taiwan |

Weighing machine speed: 30 boxes/minute

For 4000 boxes / hour, 2 weighing machine + 1 packing machine (At least 2 weighing machine, recommend 3 )