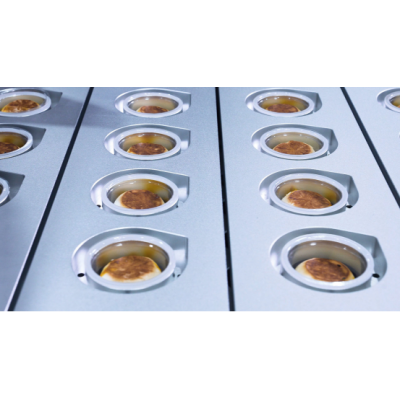

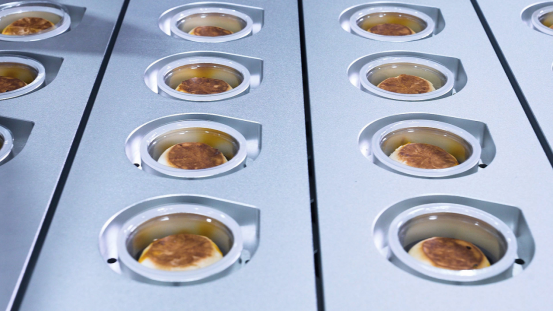

Introducing our innovative Sealerall Conveyor Belt Sealing Machine, designed specifically for the moon cake industry. This high-efficiency solution allows for the fresh keeping of your delectable creations, handling six boxes at a time with ease.

With our advanced sealing technology, you can ensure that each moon cake retains its flavor and quality, enhancing your production process and satisfying your customers. Elevate your business with a success solution that meets the demands of the moon cake market.

Machine Function and Configuration:

1. This machine can seal six boxes at one time.

2. Six speeds: 3600-4000 pieces per hour

3. 3. Production process: can automatically drop the mooncake tray, automatically put the bottom cover, automatically throw the deoxidation bag, and automatically print the production date

4. The appearance of the machine is simple and generous, using high-quality stainless steel 304, food-grade industrial 2B plate with brushed effect, dust-proof and rust-proof, acid-resistant and alkali-resistant.

5. Purely hand-polished and polished, fine workmanship, small chassis interface, no sharp corners, conscientious quality.

6. All parts are added by CNC machine, accurate, standard, high precision, so that the whole machine can run smoothly for a long time and have a long life.

7. The chain is food-grade stainless steel 304, acid-resistant and alkali-resistant, can be directly washed with water, durable and not easy to deform.

8. Frame structure: It is welded with thick steel structure, cooled and formed for one month, and then plane-made by gantry milling machine, solid and stable.

9. The degree of automation is strong, connected to the customer's self-equipped servo filling machine, automatic air pressure sealing, and can seal six boxes at a time.

10. Sealing mold structure, stainless steel + alumina + brass, durable, no rust, fast heat conduction.

11. Servo motor drive, classic digital temperature controller, temperature balance, plus or minus 1 degree, reliable sealing, no water leakage, good surface flatness.

12. Taiwan photoelectric eye tracking to ensure that the sealing pattern is aligned and centered.

13. Delta PLC program control, Taiwan human-machine interface, fault alarm, easy to check faults.

14. Sealing material: As long as the material matches the box, it can be used, such as: plastic composite heat-sealing film or aluminum foil composite film, the film thickness is not less than 0.1MM.

15. Air pressure range: 4-8KG/CM2

16. Temperature range: 0-250 degrees

17. Power: 4500-5000W

18. Voltage: three-phase 380V, 60HZ

19. Packing method: wooden Box

Gifted Accessories:

ten heating tubes, two 40A solid-state ones, two 4V210-08 solenoid valves, two push-button switches, and thermocouple.

List of Electrical Accessories:

1. Host structure: stainless steel 304 frame full thickness 3.0

2. Sealing mold: six series aluminum, 6061 aluminum alloy, non-casting acidified aluminum

3. Sealing hot plate: brass, non-aluminum plate

4. Human-machine interface: Taiwan Weilun

5. Solenoid valve: Taiwan AirTac 4V210-08

6. Air switch: France Schneider

7. Main cylinder: Taiwan AirTac SC120*50

8. Switch power supply: Taiwan Delta S-360-24

9. Temperature control solid state: South Korea

10. Drive motor: Taiwan servo

11. Temperature control meter: Japan Fuji

12. PLC: Taiwan Delta

13. Repeater: France Schneider

14. Circuit breaker: France Schneider

15. Inverter: Taiwan Delta