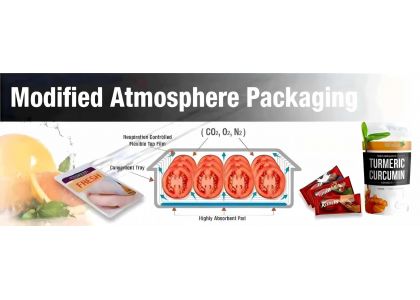

How Does MAP Modified Atmosphere Packaging Work?

Modified Atmosphere Packaging (MAP) is a technique used to extend the shelf life of perishable products by modifying the gaseous environment within a package. This involves replacing the air inside the package with a specific gas mixture, often reducing oxygen and increasing carbon dioxide and/or nitrogen. This controlled atmosphere helps to slow down spoilage, microbial growth, and oxidation, preserving the quality and freshness of the product.

Here's a more detailed look:

-

Gas Replacement:

MAP replaces the normal air (21% oxygen, 78% nitrogen, 0.04% carbon dioxide) inside a package with a tailored gas mixture.

-

Key Gases:

The most common gases used are carbon dioxide (CO2), nitrogen (N2), and sometimes oxygen (O2).

-

Reduced Oxygen:

Lowering oxygen levels inhibits the growth of aerobic bacteria and slows down oxidation, a major cause of food spoilage.

-

Increased Carbon Dioxide:

CO2 can inhibit the growth of many microorganisms and also helps maintain moisture, which can be important for certain products.

-

Nitrogen:

Nitrogen is often used as a filler gas to displace oxygen and prevent package collapse.

-

Extended Shelf Life:

MAP can significantly extend the shelf life of perishable products, from fresh produce to meat and seafood.

-

Preservation of Quality:

It helps maintain the freshness, color, and nutritional value of the product.

-

Reduced Need for Preservatives:

MAP can reduce or eliminate the need for chemical preservatives.

-

Improved Transportation:

By extending shelf life, MAP allows for wider distribution and transportation of fresh products.

Examples of Products Commonly Packaged with MAP:

- Fresh meat, poultry, and seafood

- Passive MAP: Relies on the selection of appropriate barrier packaging materials to maintain a modified atmosphere.

MAP vs. Vacuum Packaging:

While both techniques extend shelf life, MAP differs from vacuum packaging. MAP modifies the gas composition, while vacuum packaging removes the air. Vacuum packaging can be cheaper and suitable for products where a modified atmosphere isn't essential.

Challenges and Considerations:

-

Gas Permeability:

Packaging materials must have appropriate gas barrier properties to maintain the desired atmosphere.

-

Product Specific Needs:

The optimal gas mixture varies depending on the product and its specific spoilage mechanisms.

-

Potential for Anaerobic Growth:

In some cases, reducing oxygen can create an environment for anaerobic bacteria, so careful consideration is needed.