Product Overview:

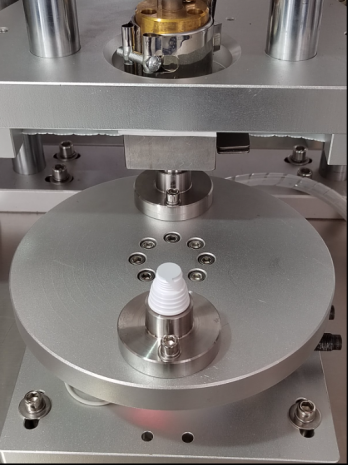

This machine is a film sealing machine for ultra-small-caliber bottles developed according to customer requirements. It is suitable for various reagent tubes and facial cleanser tubes, both square and round. The sealing film is a roll film, which is automatically punched, hot-pressed and sealed. The finished product is automatically produced. The sealing effect is beautiful and generous, saving human resources and improving production efficiency.

Machine functions and configurations:

1. One out, automatic in and out, push-pull style

2. Production speed: 500-600/hour

3. Production process: manual bottle/tube insertion, foot-operated start switch, automatic punching, automatic sealing.

4. Program control, stable and reliable.

5. The human-machine interface is touch screen control, simple operation, and the machine operation status can be monitored at any time.

6. Classic digital display temperature control meter, temperature difference of plus or minus 5 degrees, good sealing effect.

7. Precision guide rail, smooth walking, accurate positioning.

8. Taiwan photoelectric eye tracking, electrical integration.

9. Sealing diameter: 6-25mm can be customized

10. Sealing material: plastic composite film, aluminum foil composite film, PP, PVC, PE, PET, PS are all available.

11. The size of the sealing film is the same as the bottle mouth, the seal is tight and the appearance is beautiful.

12. Air pressure range: 4-8KG/CM2

13. Temperature range: 0-300 degrees

14. Power: 500-1000W

15. Voltage: 220V

16. Machine appearance: stainless steel

17. Net weight: 85KG

18. Packing method: wooden box

19. Accessories: one instruction manual, one hexagonal wrench, one cross screwdriver, one paper tube.